Blakemere offers a comprehensive range of services and equipment to ensure that your assets continue to perform in the most challenging environments. We excel at developing solutions to combat the degradation of marine assets and restore functionality where it’s been lost.

Damage Remediation

We can fix anything. From catastrophic damage and trawled

subsea infrastructure, to failed mechanisms and broken

interfaces; we will restore functionality to your subsea assets. In fact, some of our flagship projects have come about when it’s all gone horribly wrong:

- A semi-automated remote flange bolting system after a christmas tree was snagged by an anchor chain.

- A subsea machining tool that restored the sealing faces of a well head following a (very large) dropped object.

- Restoring the functionality of a displacement initiator after it was trawled by a rampaging rig in a cyclone.

- Fixing a leaking subsea safety valve control circuit by replacing a coupler on the tubing hanger. That’s like changing a spark plug on your car with the bonnet shut. Underwater. With a robot.

Sometimes the biggest challenge is convincing the client we can do what we say we can, and this is where our track records and case histories speak for themselves. Check them out.

Marine Growth Removal

From bulk removal of marine growth to polishing hydraulic

sealing interfaces on permanent subsea hardware, we have

developed a tool to address your issue. If not, we’ll create one. We specialise in all manner of cleaning brushes, both custom and generic, and acid supply systems of various capacities and designs. We also have HP and UHP zone rated pumps that we use for cleaning when the growth is more obstinate or the surface finish requirements are greater. Check out our case histories for examples of how we combine bespoke design with a light touch, or brute horsepower, to clean your subsea assets.

Calcareous Deposits

Calcareous deposits are an unwanted by-product of protecting equipment against corrosion and the bane of all operators’ lives. Our track record of equipment that addresses the effects of these deposits is supported by our ability to deliver acid in any quantity required. We specialise in getting acid to where it’s needed and keeping it there long enough for it to do its job. Think you can’t get acid where you need it? Ask us, we love a challenge.

Subsea Distribution System Remediation

Fact: water and electricity do not mix. Our mothers told us this and our professional lives as subsea engineers only support what she said. The operation of many of your subsea assets is reliant upon a complex subsea communications network of EFLs, SDUs, UTAs, UTHs, EDUs, SCMs, EDMs, and many other TLAs.

Fact: Blakemere has an ever-growing track record of restoring functionality and improving the serviceability of many elements of the subsea distribution systems of the oil majors.

SCM Remediation

Your subsea control modules are fundamental in sustaining

subsea production. Yet despite the criticality of uninterrupted service, SCMs typically require intervention or recovery more frequently than planned. Fine tolerances and close-fitting mechanisms combined with calcareous deposits and physical inaccessibility have thwarted many attempts to recover SCMs. Many issues have been encountered recovering SCMs that have been installed only a short period of time, some less than 12 months.

The greatest success during intervention with these production-critical components frequently depends upon the application of acid at the affected interfaces and the maintenance of high concentrations for prolonged periods. However, this fundamental requirement is often absent in the design of SCMs and their interfaces with subsea assets. Over time this has necessitated the development of numerous strategies and equipment to address these oversights in design.

Blakemere has assisted numerous operators in many varied

ways in the recovery of obstinate SCMs and the return of the permanent mounting interfaces to as-new condition. Existing equipment and capabilities within this solution line include:

- Acid shrouds that envelope the entire SCM and mounting

base to effectively and efficiently soak all components in acid, reversing the effect of calcareous deposits created by cathodic protection. If the gap between the SCM and the guide funnel is obstructed or insufficient, there’s a jacking tool to create the space required. - Shrouds and acid injection systems can be deployed to envelope and soak the mounting base as a method of remediation, or as a precursor to further remedial intervention, once the SCM has been removed.

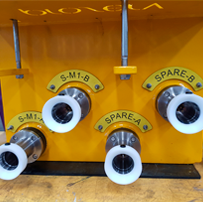

- Cleaning tools that safely and efficiently return the permanently installed hydraulic couplers to as-new condition using a combination of cleaning pads and acid delivered directly to the mating faces. For speed and efficiency, the couplers are cleaned four at a time (see the before and after images in the Inpex presentation).

- Tooling that drills through the lower skirt of some SCMs that obstruct access to the hydraulic couplers and injection wands that deliver acid directly to the affected areas.

- Jacking tools that apply a force directly between the mounting base and the underside of the SCM. The direct load path allows greater forces to be applied than possible through traditional extraction methods.

Anode Retrofits and Life Extension

Your infrastructure is still working and the price of oil is…ok. You want your asset to keep producing beyond its design life but nothing lasts forever, especially subsea. Blakemere has delivered hundreds of items to field operators seeking to renew the performance of their CP systems, or otherwise extend the serviceable life of their assets. From a simple clamp and a cable through to an anode skid, we have the facilities to design and fabricate what you need.

Sometimes the problem is a little more serious than the addition of an anode skid. You may be unlucky enough to have a fatigue crack in a jacket member and require a subsea machining tool to follow the crack and create a weld preparation, or even cut out a large coupon with an automated tool. And then perhaps you need a dry welding habitat to complete the remediation. Yes, we can do that too because we’ve done it before.